History and background

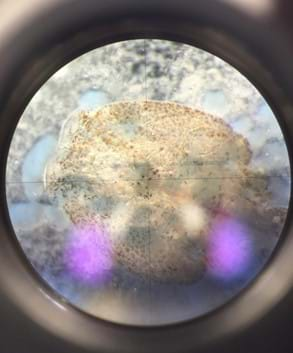

The idea to treat salmon against salmon lice infections with particulate quicklime (CaO) was initially conceived by two researchers at the Institute of Marine Research, who since 2008 was investigating particulate CaO used to kill sea urchins. They observed that fish were swimming through the CaO clouds seemingly unaffected. This observation brought forward the idea that CaO may be sensitive to sea urchins and other creatures with a hydrophobic surface, and not to, e.g. fish with a hydrophilic surface. The method was then tested in small fish tanks, net pens and clinical trials. The results from these trials demonstrated that the method was effective against salmon lice (lepeophtheirus salmonis).

In 2012 the company was founded and later same year Franzefoss Minerals (FMI), the largest producer of lime and limestone products in Norway, became a shareholder. The following year Norsk Innovasjonskapital II AS became Seacalx largest shareholder and the owner constellation was established.

Through an extensive R&D programme the interdisciplinary team of Seacalx has demonstrated a solid effect on the free-living stages of salmon lice in laboratory studies, and since 2015 the research focus has been directed towards the product's potential as a preventive de-lousing agent. Our R&D activities have been carried out in cooperation with the most recognized research communities combined with small and large contributors in the aquaculture industry.

In 2018 the company was granted permission from the Norwegian Medicines Agency (NoMA) to further investigate the effect in clinical trials, but a consistent high preventive efficacy was challenging to demonstrate under field conditions with the existing concept. A strategy to further develop the project was therefore established, and the company applied for research licences in aquaculture to bring the important research further forwards.

In May 2021 Seacalx AS was granted three licences for research purposes and years of research are now being further materialized to optimize our environmentally friendly product. Gratanglaks AS is new owners and has strengthened the project with extensive on-site aquaculture knowledge and breeding infrastructure.

After nearly 10 years of research, Seacalx has now reached the biggest milestone in the company's R&D programme to date and is facing an exciting time ahead in order to develop an eco-friendly product for preventing salmon lice infections in aquaculture plants.

About the product

The product is based on particulate calcium oxide (quick lime), and the unique product properties are created through a specialized production process and a specific particle composition.

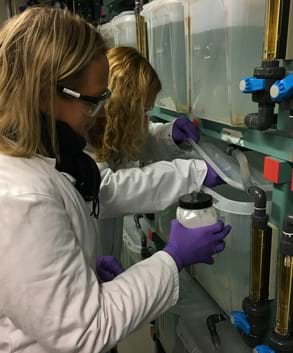

The product is applied to the net pens by a special designed spreader equipment where CaO is mixed with sea water and pumped over the net pen surface. The particle size range of the product causes a differentiated reaction between calcium oxide and lice larvae throughout the water column in which the smallest particles react quickly in the upper water masses, while larger particles prolong the effect in the deeper water column (approx. 5 meters).

The competitive advantages of the product are:

- No handling of the biomass

- No need to starve before treatment

- No withdrawal time

- Environmentally friendly

The supplier of the product, FMI is Norway's largest lime producer. They produce varieties of pure calcium-containing products and have a high level of expertise in various lime products. The relevant grades of calcium oxide for this product, is produced in accordance to the Good Manufacturing Practice (GMP) standard with a manufacturing license from the Norwegian Medicines Agency (NoMA).

Seacalx' product has been classified as a veterinary medicinal product by NoMA. In parallel the company has applied for a biocidal product authorization of an identical concept in relevant markets, and the competent authorities has issued a positive opinion for biocidal product approval. The application is currently being assessed by the concerned member states, and biocidal product approval in relevant markets is expected soon.

Seacalx aim to be a future supplier of environmental friendly products. Due to the reaction pattern of CaO, the product will end up in the environment as stable and non-reactive compounds - mainly calcium carbonate, in addition to other compounds that do not harm the environment, such as gypsum. Due to this environmentally friendly profile, the product is listed on PLONOR (OSPAR Commission: Pose Little Or No Risk to the Marine Environment).